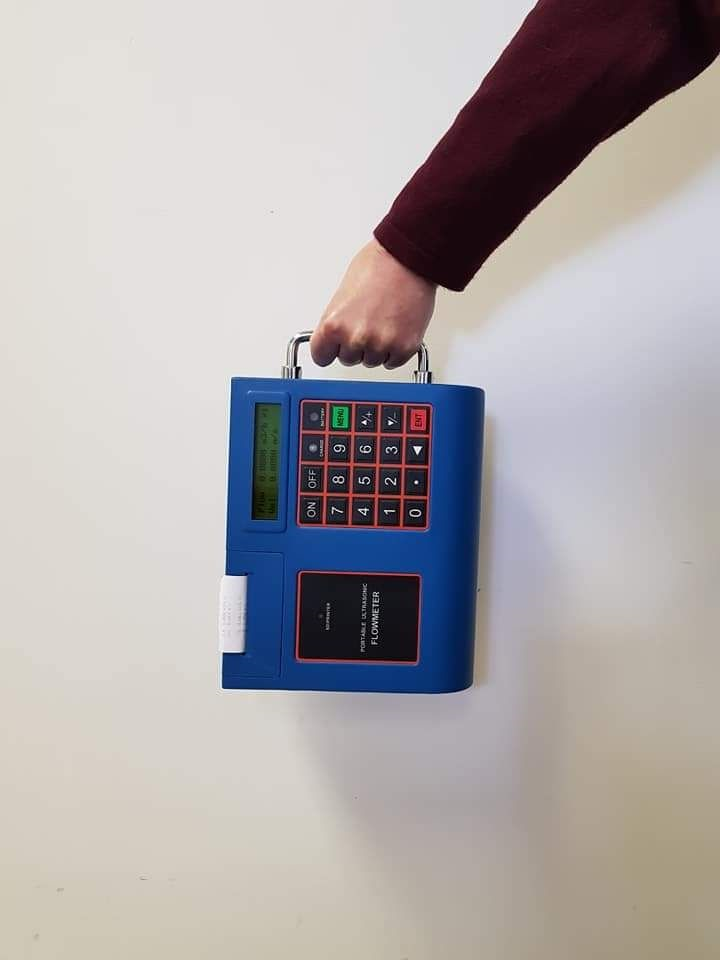

Portable Ultrasonic Flow Meters

Non-intrusive flow rate and totalised flow measurement

Suitable for :

- Clean for clean water with few bubbles or suspended solids

- Mininum pipe diameter 25mm

- Straight pipe without bends or flanges

Not suitable for :

- Stainless steel or lined pipes

Model TUF 2000 P - With Data Logging Fixed Ultrasonic Flow Meters

- Non intrusive, ultrasonic flow meter suitable for flow surveys with paper print out, saving to SD card and optional 4-20mA

- High accuracy : +/1 %

- Robust metal enclosure

- Wide measuring range : DN 25 to DN 6000mm (with 3 different sensors sets, used one set at a time)

- Built-in thermal printer

All kits include :

Aluminium carry case containing ultrasonic flowmeter, sensor set (-30 to 90°C) (3 different sensor sets to choose from), SD card and card reader (if datalogging is required) 5m of cabling, ultrasonic gel, strapping, tape measure, 2 paper rolls and manual

Optional Extras :

High termperature sensors (-30 to 160°C), mounting brackets, ultrasonic thickness gauge, local verification certificate

Model TUF 2000 H - Without Data Logging

- Non intrusive, ultrasonic flow meter with RS 232 port

- High accuracy : +/1 %

- Wide measuring range : DN 25 to DN 6000mm (with 3 different sensors sets, used one set at a time)

All kits include :

Aluminium carry case containing ultrasonic flowmeter, sensor set (-30 to 90°C) (3 different sensor sets to choose from), 5m of cabling, ultrasonic gel, strapping, tape measure and manual

Optional Extras :

High termperature sensors (-30 to 160°C), mounting brackets, ultrasonic thickness gauge, local verification certificate