Vibration Monitoring Service

On-Site Vibration Surveys Using Qualified, Experienced Engineers With Our Own Equipment

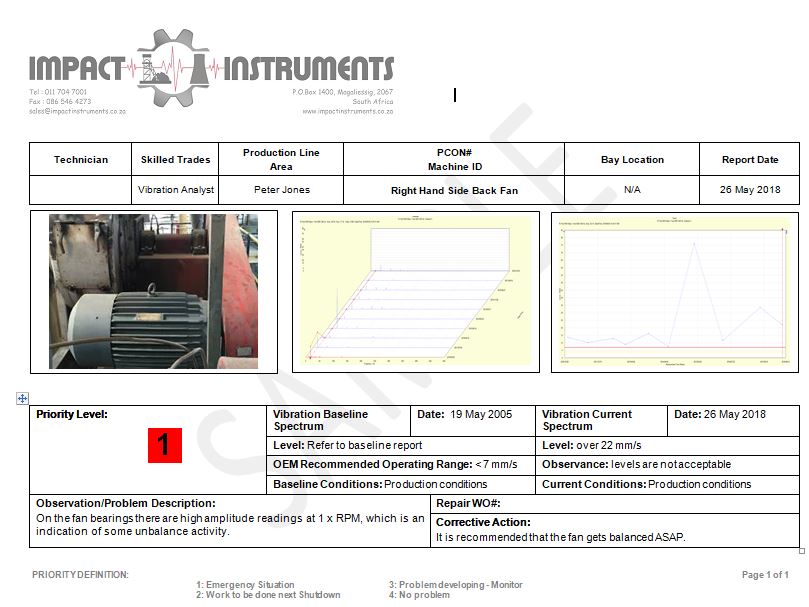

A hard copy report is supplied on completion

- Measurement location and overall vibration values at this point

- Percentage change between the last measurement and the previous measurement (only available after 2 data collections)

- Alarm status for the overall values (Alert and/or Danger)

- Diagnosis for the machine

- Recommendations

- FFT spectrum and/or time trace showing the problem on the machine

- Trend plot (available after at least 2 data collections)

- Discussion on the problems detected